SALE 48% OFF

BATTERY

For iPhone 5/5S/SE/6/6P/6S/6SP/7/7P/8/8P/X/XR/XS/Xs Max

is most important

Test view

Safety

CE RoHS MSDS UN38.3

make sure good quality

6 protection for safe use

Overcharge

Protection

Overdischarge

Protection

Over Current

Protection

Short Circuit

Protection

Overvoltage

protection

Temperature

protection

Details determine success

FPC

Use copper foil material which purchased

from public company, with good flexibility,

high conductive, excellent heat exchange

material.

DETAIL SHOW

Hardware Interface

Precision mold which degree of precision is

0.001 mm, can touch the phone connector

perfectly, Gold Plating touch spot , low

internal impedance, never oxidation.

Battery Protection Board

Protection board use 4 layers copper

(low internal resistance). Each

piece protection board pass more than 10

testing process to make sure stable quality

Battery Models

Imported full automatic production lines

Our Factory

Pruduce Battery for more than years

Our factory founded in 2007. Our $3 Million state-of -the art production

facility comprises 6 automatic assembly lines. They are very advanced

facilities in mobile phone lithium battery industry. We have highly

professional R and amp; D and design teams.

Our batteries have CE RoHS MSDS UN38.3 Certification, the

identification for Marine and air transport.

Our valued clients are spread across the world, including United States,

Germany, France, Spain, United Kingdom, Netherlands…

12

Producton flow

Cycle life test

Material feeding

Automatic welding

Printing

Edge protective sticking

Appearance checking

Put in warehouse

Labels and packing

Real phone test

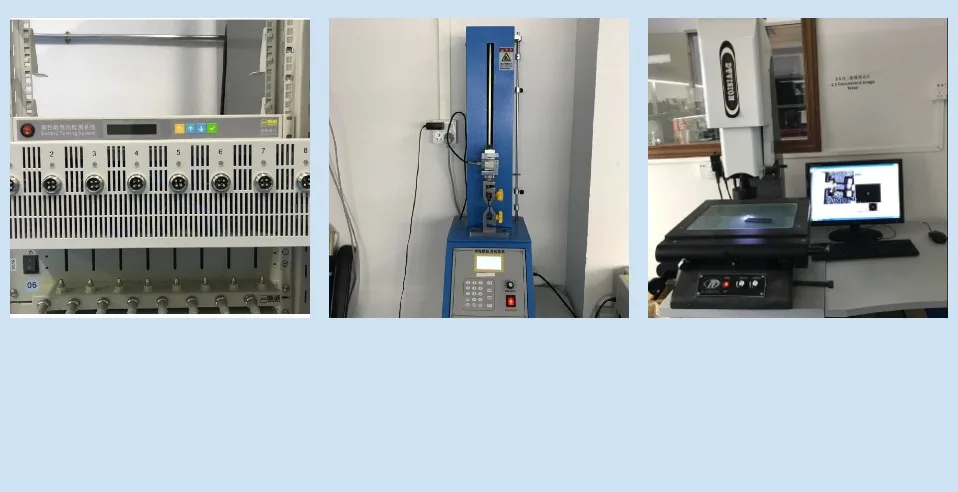

Advanced testing equipment

automatic Laser

Quality inspection

Harsh quality control inspection process

Batteries and protective plat

Welding process

Semi-Automatic

Protection Board Test

Protection board incoming

inspection

High Precision Aging Cabinet

Battery / cell aging test

Battery matching data acquisition

Sample cell quality data collection

Multi-Channel Test Sub-cabinet

High temperature Machine

High and Low Temperature and

Humidity Test Machine

Battery spot checks

Battery / battery charging test

Components accessories high

temperature standing

Batteries at high temperature

from the power consumption

Battery high temperature performance

safety test

Battery / cell safety test

Battery / cell high and low

temperature performance test

High and low temperature reliability

test of componentstest

2.5 Dimensional Image

Measuring Instrument

Microcomputer Rally Machine

High Current Aging Cabinet

Battery / cell safety test battery

Protection board Safety test

Production test Reliable test

Component high current test

Incoming reliability testing

Welding reliability testing

Laser spot welding reliability testing

Incoming size

Engineering sample measurement

dimensions

Product analysis

Product quality comparison

Why choose our battery

AYJ Factory

Full automatic production line

Others

Small Manufacturers, handiwork

Automatic production line avoid the quality problems

by hand, high efficiency with good quality

Bad environment, manual operation, it is easy to appear

mistake if by full manual operation, low efficiency, bad quality

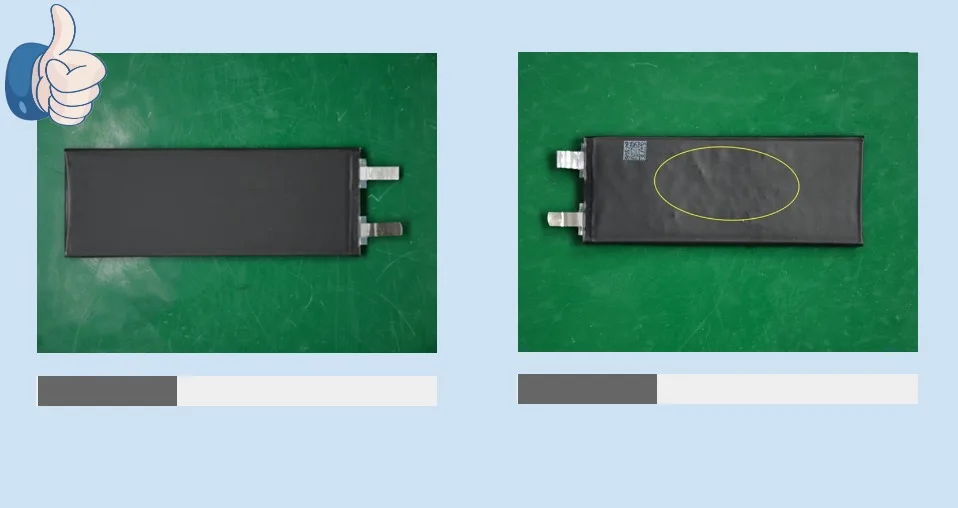

AYJ Battery Cell

after 650 times cycle life

Others

after 100 times cycle life

The surface of the battery cell is still smooth, thickness

only increase 0.1mm, it can be used normally

There will be particle from the battery cell inside, thickness

increase 0.2mm, easily caught fire and explode the screen

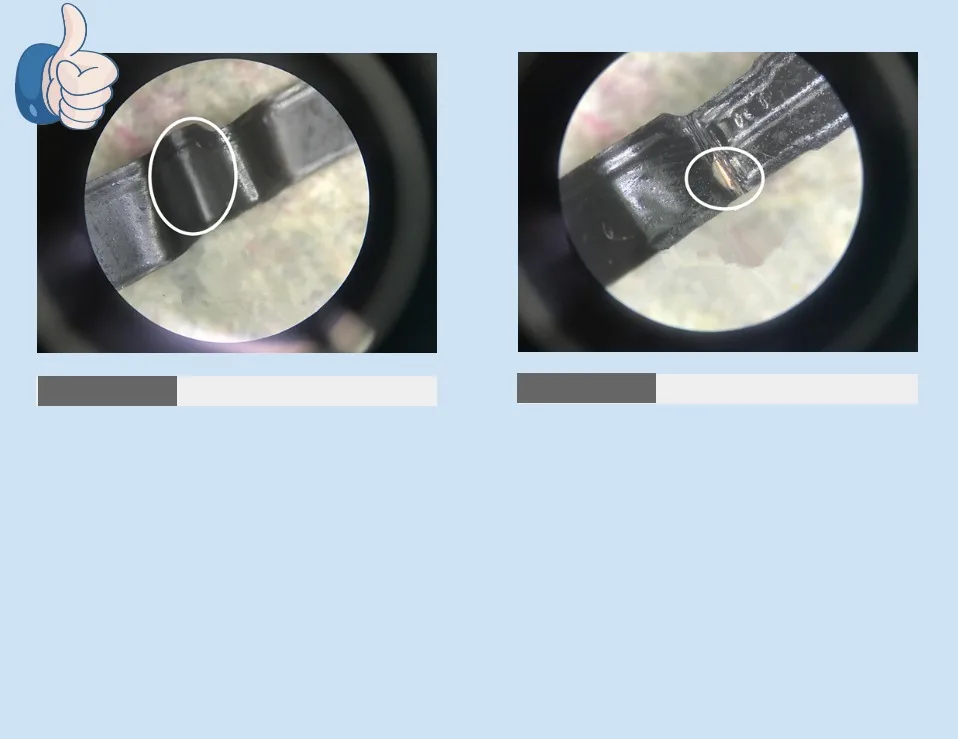

AYJ welding machine

¥300,000 Laser welding machine

Others

¥2000 Foot-type welding machine

We use big brand Automatic laser welding machine,

computer control to make sure welding precision,

fastness, high efficiency with good quality

Foot-type welding machine, melted nickel by pressure,

large current ,high frequency, high temperature

High frequency is easy to breakdown the separator between

positive pole and negative pole.

Broken the protection board IC to led fire or explosion

Pressure by foot is not stable, easy to crushing damage the

PCB

AYJ FPC

after 3 times bending

Others

Common FPC after 3 times bending

FPC problem is the most often problem during use.

AYJ FPC use copper foil material which purchased

from public company, good flexibility, high conductive,

excellent heat exchange material.

XRM FPC can bear about 5KG tension(pulling force

testing Machine)

Greatly reduces FPC break off problems.

Common FPC Easy to break off ,bad flexibility , low

conductive, high internal resistance(FPC high resistance will

cause temperature rise when FPC overcurrent, even fire)

Don’t hesitate any more

We are your correct choice

BUY NOW

SHOPPING TIPS

PROVIDING BEST SERVICE

HIGH QUALITY SERVICE,LET SHOPPING NO WORRIES

1) You have 7 days to contact us and 14 days to return it from the date it was received. If this item is in your possession more

than 7 days, it is consideredused and WE WILL NOT ISSUE YOU AREFUND OR REPLACEMENT. There are NO EXCEPTIONS!

Shipping cost is bear by both seller and buyer in half.

2) All returned items MUST BE in the original packaging and you MUST PROVIDE us with the shipping tracking number,

specific reason for the return, andyour new tracking number.

3)We will refund YOUR FULL WINNING BID AMOUNT, upon receipt of the item in its original condition and packaging with all

components and accessories included, AFTER BOTH Buyer and Seller cancel the transaction from Aliexpress. OR, you may

choose to have a replacement.

PAYMENT

Currently, you can pay using Boleto, Visa, MasterCard, QlWl, Western Union, Maestro debit card, WebMoney and bank transfer.

More payment options will be available on AliExpress in the future.

SHIPMENT

AlI our items will be shipped to buyer’s address which offered by buyers, please confirm your address before payment.

We will send the items within 3 Business days once your payment is completed. (Holidays may be extended)

COLOR MISMATCH

Differences in color may be caused by some other reasons , Please in kind prevail.

FEEDBACK

Your satisfaction and positive feedback is very important to us. Please leave feedback and 5 stars if you are satisfiedwith our

ltems and services.

If you have any problems with our items or services, please feel to contact us first before you leave negative feedback. We will do

our best to solve any problems and provide you with the best customer services.